Flash & Deflashing

“FLASH” is a surplus rubber that oozes out between the two halves of mold during the molding of rubber parts. Various techniques have been employed by rubber manufacturers but flashes cannot be avoided. Even the modern technology such as ‘flash less’ molding technique results in the formation of micro line called flash line. This flash occurs in the regions where different sections of mold brought together (and apart) is known as ‘parting line flash’. The remaining mold flash typically traces around where the different mold section ‘mate’ and is created when the liquid mold material escapes out of the mold cavity into the tight area where the mold sections press one another.

Mould flash can be caused due to the old and worn out mould cavities due to continuous usage which leads to mould mismatch and thereby increasing flash in the component. Most of the time, type of the material being molded and its attendant viscosity in the liquid form is the primary factor that leads for the formation of unwanted mold flash.

Deflashing is the process of removal of these excess flash.

Cryogenic Deflashing

Cryogenic deflashing is a deflashing process that uses cryogenic temperatures to aid in the removal of flash on cast or molded workpieces. These temperatures cause the flash to become stiff or brittle and to break away cleanly. Cryogenic deflashing is the preferred process when removing excess material from oddly shaped, custom molded products.

Cryogenic deflashing provides various advantages over manual deflashing and other traditional deflashing methods.

Manufacturing high performance materials for growing markets such as automotive and electronic components certainly has its challenges. Molded or machined parts must meet strict tolerances and intricate finishes. When elastomer parts are manufactured by way of injection, transfer or compression molding, a thin membrane of material, called flash, remains along the mold-parting line. Flash is excess, unwanted material that must be removed from finished parts.

Several techniques can be used to remove flash:

Several techniques can be used to remove flash:

Manual tear trimming or manual cutting is the process of manually removing tear trim beads from around the parting line of the finished part. While the capital cost is low for this technique, the process is labor intensive. In addition, manual tear trimming has relatively high variability in quality and production rate due to geometry of the part.

ie punching to remove flash consists of placing the molded product into a die, shaped like the finished part, and simultaneously punching the parts out of the flash mat (similar to using a cookie cutter). While this method provides somewhat consistent quality with a low capital cost, the process is labor intensive, resulting in lower production output.

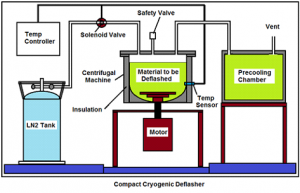

Cryogenic deflashing is a process that uses the extremely low temperature of a cryogen such as liquid nitrogen (LIN) to remove flash. It accomplishes this by embrittling the rubber or plastic parts and subjecting the material to mechanical stress through tumbling and simultaneous media blasting

By simply changing the process parameters and media size, cryogenic deflashing is amenable to many molded products, including O-rings, grommets and gaskets. With a low to moderate capital cost, cryogenic deflashing enables a consistent deflash quality and high production rate. A well-designed and operated system can result in lower overall labor and operating costs.

No deflashing process can make up for poor mold design or mold wear that leads to a poor or nonexistent parting line. The types of materials that may benefit from cryogenic deflashing can be seen in table 1, and the types of molded parts that may benefit from cryogenic deflashing can be seen in table 2. Cryogenic deflashing is ideal when flash is thin with a good base or transition point where the flash can break away from the molded part in a precise manner. This transition in part thickness is known as the parting line and is a key factor in overall deflashing quality. Cryogenic deflashing is not ideal for thin cross-ectional parts such as diaphragms; parts with thin, sharp edges; and certain medical-related products due to contamination and cleanroom regulations.

Safety is paramount in any manufacturing process, and cryogenic deflashing using liquid nitrogen is no exception. When handled properly, liquid nitrogen is a safe and effective addition to many types of processes. Because liquid nitrogen can reach temperatures of -320°F (-195°C), transfer equipment and piping must be insulated and proper personal protective equipment (PPE) must be worn to avoid cryogenic burns. Additionally, when liquid nitrogen vaporizes into a gas, there is a volume expansion of almost 700:1. Therefore, piping and equipment must be designed for adequate ventilation to avoid overpressurization and rupture. Although nitrogen is nontoxic and largely inert, it can act as a simple asphyxiate by displacing the oxygen in air. For this reason, work areas must be ventilated properly. Oxygen analyzers also should be used to monitor oxygen levels in the work

area. Be sure to review the proper safety information and consult an industry professional for appropriate guidance. To optimize operating costs, part quality and production output, it is important to properly manage liquid nitrogen consumption. Many factors— such as equipment, type of part, piping and geometry — can impact liquid nitrogen consumption rates during the cryogenic deflashing process.

When selecting equipment, keep in mind:

Tumbler, shot blast and load capacity affect overall operating efficiency.

Age, Condition and Maintenance History.

Older equipment tends to be less efficient due to equipment design, deterioration of the insulation surrounding the deflashing chamber, lack of precise temperature control and poorly maintained LIN injection piping.

Controls. Accurate temperature control of the deflashing chamber is achieved through proper placement of the LIN injection orifices and thermocouple probe to optimize deflashing quality and LIN consumption. Accurate control of basket-, belt- or impeller- wheel speed is required to further optimize finish quality and system efficiency.

Factors of importance regarding molded parts include:

Durometer. Durometer can influence embrittlement temperature and LIN consumption. Higher durometer (harder) compounds embrittle at warmer temperature settings and require less LIN to cool. Lower durometer (softer) compounds embrittle at colder temperature settings and require more LIN to cool.

Parting-Line Flash Thickness.

Parting-line flash thickness will determine the ability of the system to finish the molded part in conjunction with cycle time and LIN consumption. Thicker flash is more difficult to remove and requires longer deflash cycle time, resulting in higher LIN consumption. Optimum parting-line flash thickness is 0.001 to 0.005”. Mold design and condition are key to optimum finish quality and LIN consumption. Part Geometry, Configuration and Cross-Section Thickness. The geometry of the molded parts also

| Neoprene Rubber |

| Nitrile Rubber |

| Butyl Rubber |

| Styrene-Butadiene (SBR) Rubber |

| Ethylene Propylene Diene Monomer (EPDM) Rubber |

| Silicone Rubber |

| Liquid Crystal Polymers (LCPs) |

| Thermoset and Thermoplastic Plastics |

TABLE 1. Some materials are better suited for cryogenic deflashing than others.

| O-Rings and Gaskets |

| Medical Implants, Catheters |

| Electronic Connectors, Insulators |

| Valve Stems, Washers, Fittings |

| Face Masks, Goggles |

| Grommets |

| Seals |

| Mountings |

| Bushings |

This schematic depicts a cryogenic deflashing process using liquid nitrogen. sing the very low temperature of cryogens like liquid nitrogen, cryogenic deflashing temporarily embrittles residual material for removal when subjected to stress applied though tumbling and media blasting.

loading for the given equipment size. Consideration also must be made for deflashing quality relating to flash thickness, part geometry and mold condition. The following parameters are also important for conducting cryogenic deflashing trials:

loading for the given equipment size. Consideration also must be made for deflashing quality relating to flash thickness, part geometry and mold condition. The following parameters are also important for conducting cryogenic deflashing trials:

Media Selection. Proper selection of media type is based on the geometry of the part/product. Temperature. If the flash is still present on the part and is flexible after tumbling, the part was under- embrittled and temperature should be lowered. If the part is damaged or broken, it likely was over-embrittled, and the temperature should be raised.

Throw Wheel Speed. The throw wheel is the impeller wheel that accelerates the blast media. If the geometry of the part is thin, a lower wheel speed should be used. On the contrary, if the geometry of the part is thick, use a higher wheel speed. The presence of sharp, delicate edges dictates using a lower wheel speed.

Ongoing Process Management and Optimization

Changes will occur over time. It is a part of every operation. It is important to re-evaluate your approach when new parts are introduced or when your process begins to experience unexpected issues from known or unknown changes.

| Compound | Deflashing

Temperature (°c) |

| Neoprene | -73 |

| Nitrile | -38 |

| Natural | -70 |

| EPDM | -54 |

| Viton | -15 |

| Silicone | -120 |

Cryogenic deflashing of molded or machined parts has become an increasingly important option for meeting the strict tolerances and intricate finishes of high performance materials used in today’s growing markets such automotive and electronic components. Using the very low temperature of cryogens like liquid nitrogen, cryogenic deflashing temporarily embrittles residual material for removal when subjected to stress applied though tumbling and media blasting. By employing this method, manufacturers can benefit from consistently high production rates and product finish quality, resulting in lower labor and operating costs. A cryogenic gases application specialist can help identify the type of equipment best suited for a deflashing operation as well as test a variety of process parameters to help optimize productivity.